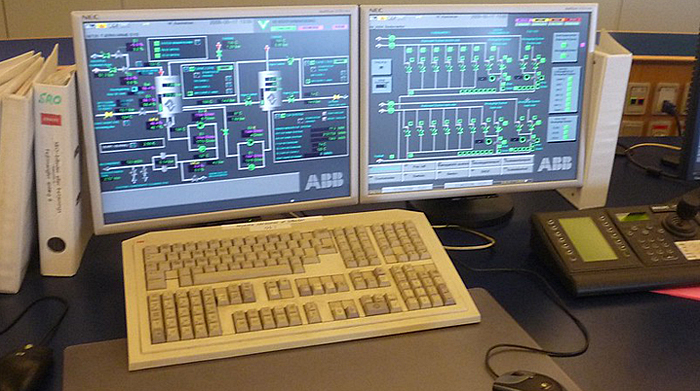

Overview of SCADA Systems in the Electric Utility Industry

Image courtesy of Green Mamba under Attribution-NoDerivs 2.0 Generic License, resized to 700 x 391 pixels.

For today’s post, I thought I’d provide a refresher/primer on SCADA systems.

Simply put, Supervisory Control and Data Acquisition (SCADA) systems play a crucial role in the utility industry, offering unparalleled capabilities in monitoring, controlling, and managing power generation and T&D infrastructure. These systems have revolutionized the way utilities operate, enhancing efficiency, reliability, and safety across the board.

Components and Functions of SCADA Systems

At the heart of SCADA systems lies a network of sensors, Remote Terminal Units (RTUs), Programmable Logic Controllers (PLCs), and Human-Machine Interface (HMI) software. These components work in tandem to gather real-time data like voltage levels, current flow, equipment status, and environmental conditions from various points across the grid (i.e., substations, power plants, transmission lines, etc.).

One of the primary functions is monitoring – SCADA continuously collects and analyzes large volumes of data to provide operators with insights into the health and performance of the grid. By monitoring key metrics in real-time, operators can quickly identify anomalies, diagnose issues, and take proactive measures to prevent potential disruptions or failures.

In addition to monitoring, SCADA facilitates remote control and automation, enabling operators to execute commands and adjust system parameters from a centralized location. For instance, if a substation detects an overload or fault, SCADA can automatically reroute power flows or isolate affected sections to mitigate the impact. This capability not only minimizes downtime but also enhances grid resilience and reliability.

Furthermore, SCADA systems play a pivotal role in optimizing grid operations and resource allocation. By analyzing historical data and forecasting future demand patterns, utilities can fine-tune generation schedules, optimize transmission routes, and allocate resources more efficiently. This proactive approach not only maximizes the utilization of existing infrastructure but also minimizes operational costs and environmental impact.

Finally, SCADA systems help enhance employee safety. By remotely monitoring equipment status and environmental conditions, operators can identify potential hazards and implement preemptive maintenance measures to prevent accidents or equipment failures.

There’s no doubt about it – SCADA systems have become indispensable tools for electric utilities of all shapes and sizes.