Benefits of Remote Power Plant Leak Detection

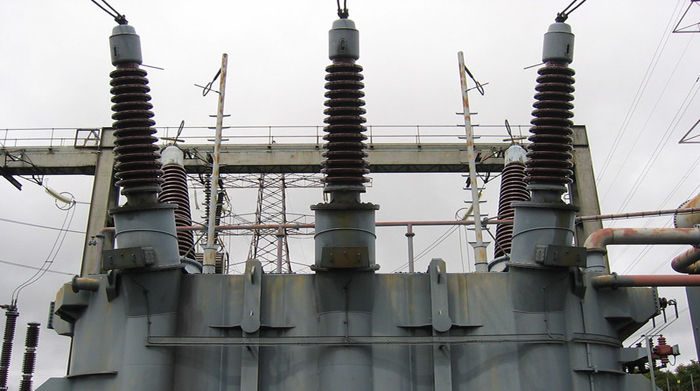

Image courtesy of Victoria Catterson under Attribution 2.0 Generic License, resized to 700 x 391 pixels.

Power plant leak detection is not something that readily comes to mind when thinking about emergency preparedness, but that doesn’t mean it isn’t important. More specifically, undetected leaks in combustion turbines, transformers and other pieces of utility equipment can take equipment offline and hurt reliability.

What Power Plant Leak Detection Entails

The long and the short of it is, many large transformers are filled with oil. It is essentially the lifeblood of the transformer. Historically, utility employees would conduct manual inspections to check for leaks, which was adequate until March 2020 when the pandemic shut everything down. Then, and still now, fewer employees are on site at any given time, which makes this manual inspection method less reliable.

The result was that many utilities started implementing methods to conduct power plant leak detection processes remotely. The strategy is generally to find small leaks before they turn into large problems, the most catastrophic of which would be an explosion that causes injuries and widespread outages and forces the replacement of an extremely expensive piece of equipment.

These systems are comprised of sensors that can detect any substance containing hydrocarbon, such as lube oil and fuel. When detected, the system will send an alert to the appropriate personnel so that the necessary repair and/or maintenance activity can be performed. Importantly, these types of sensors are not triggered by ordinary water, which makes them highly accurate.

The oil that the sensors look for is also used in high-voltage capacitors, switches, exciters, and circuit breakers, and therefore the technology is useful to detect leaks in a variety of equipment, not just transformers. The sensors are also relevant for combustion turbines (CTs), as these pieces of equipment typically fueled with natural gas and require continuous lubrication while operating. Most CTs periodically have fittings that come loose, creating a common source of leaks that can create damage and outages.

The bottom line is that, although power plant leak detection doesn’t seem particularly related to emergency preparedness, without it, incremental outages can occur. Therefore, it’s important to understand the risk and how it correlates with overall system reliability.